Wide Application Range

Modular Cleanrooms

Cleanrooms are needed in various fields including pharmaceutical compounding, medical device manufacturing, tissue & blood banks, microbiological control laboratories, and many more.

As a turn-key solution partner, we analyze your needs and use a comprehensive approach to provide you an ideal cleanroom solution in compliance with ISO14644 / FED209E requirements.

As a turn-key solution partner, we analyze your needs and use a comprehensive approach to provide you an ideal cleanroom solution in compliance with ISO14644 / FED209E requirements.

Cleanroom on

Wheels !

Kapsam mobile cleanrooms are custom-designed and easily movable throughout a facility or to a remote location and provide complete cleanroom capabilities wherever they are needed.

- Indoor / outdoor located

- Pre-engineered, self-contained

- Custom-designed per customer needs

- Ready to use single-piece construction

- Extendable widths with cascade method

- Easy to carry with 20 ft container size

- Rapid construction period

- Compliance with standard modular cleanrooms

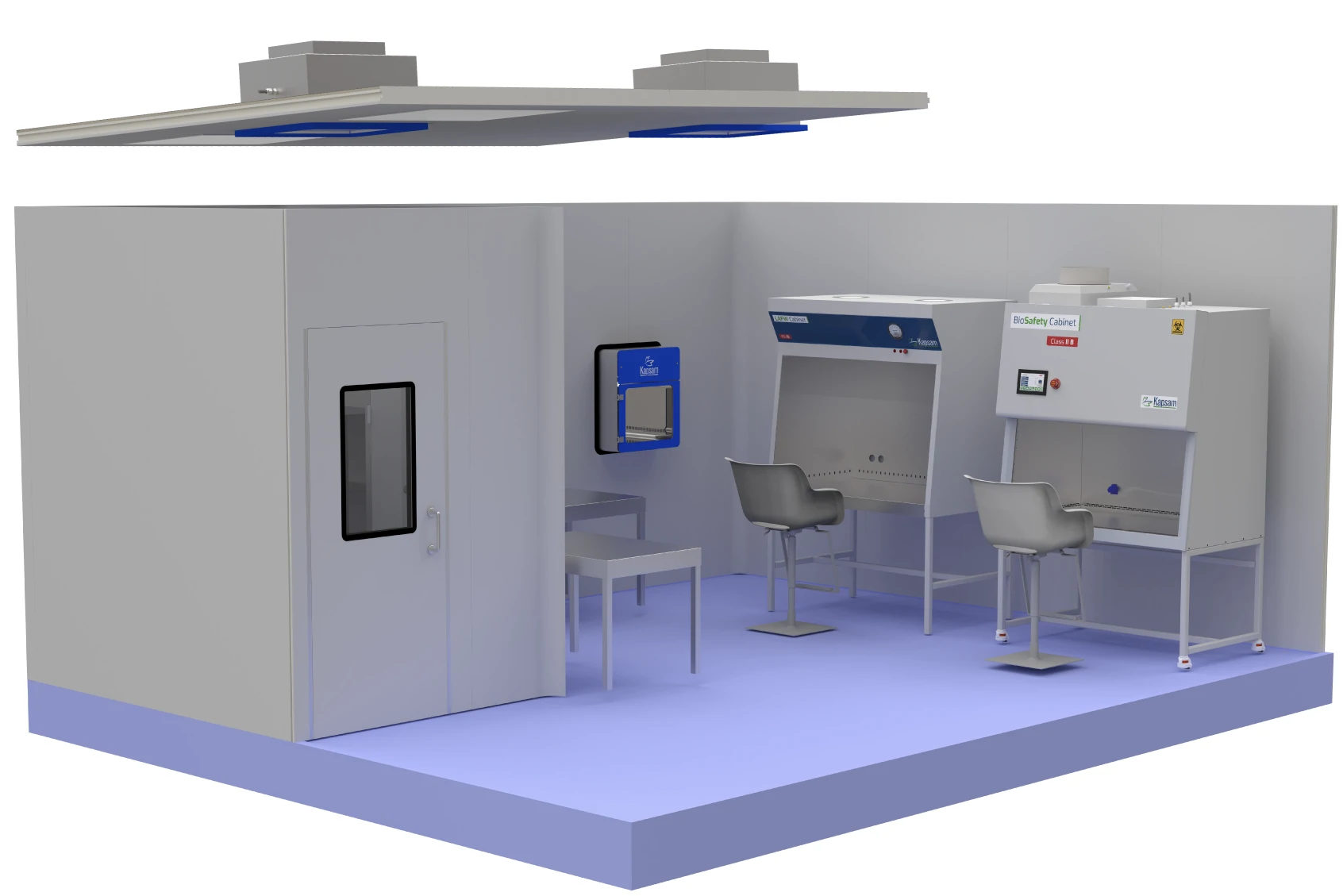

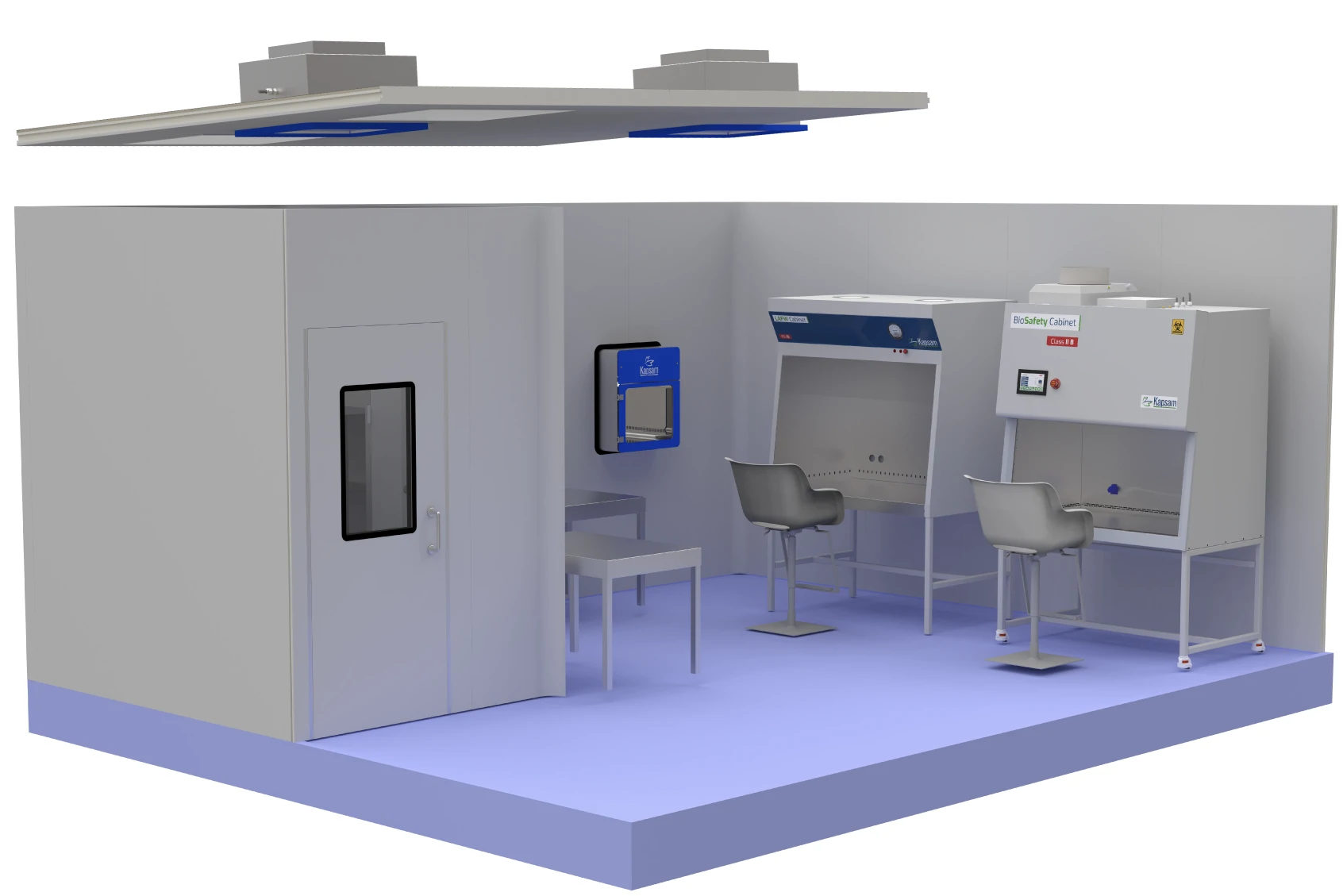

Specific Solutions for

Compounding Pharmacies

Thanks to our expertise and broad manufacturing portfolio in hazardous and non-hazardous sterile compounding areas, we are capable of offering you an ideal cleanroom solution including needed automation and software solutions in compliance with international and regional requirements.

With a 7-inch touch screen and user-friendly new interface, pharmacy pump operation is now easier than ever!

- USP <797> and <800> Compliance

- ISO Class 5 Laminar Airflow / Biosafety Cabinets (PECs)

- ISO Class 7 Buffer Area (S-PEC)

- ISO Class 7/8 Ante-Area

- Automated Compounding Systems

- Fluid Dispensing Pump

- Order Entry & Pharmacy Operation Software

- Sterile Compounding Disposables and PPEs

- Positive/negative pressure design based on the application type

System

Components

Panels

60mm sandwich-type panels that can be easily cleaned using antiseptic agents. High-density polyurethane rigid foam is injected between two PVDF-coated white heat-enameled steel plates. Hygienic type joints with resistance to scratches and chemicals. Easy-to-clean rounded corners.

Light Fittings

Airtight-type lighting fixtures that can be changed from within the cleanroom. Specific design and positioning based on the device layout, staff and material flow inside the cleanroom.

Ceilings

Sturdy and strong walkable ceilings for safe and easy access to mechanical systems without disrupting the cleanroom environment. Capable of supporting a wide variety of mechanical systems, lighting, sprinklers, HEPA filters, utilities, and small equipment.

HVAC and Filtration

Independent air treatment system for each zone with uninterruptible working in all weather conditions. 100% exhausting of the air in negative pressure cleanrooms. Three-stage air filtration: F5-F9 and H14 grade terminal filters. Terminal filtration with H14 type absolute filters in accordance with EN 1822. Separate filtering for particle sizes and carbon filter options for preventing odor and gas.

Floors

Hygienic type with resistance to scratches and chemicals, and can be applied as PVC or Epoxy according to customer preference.

Finishes

All inner/outer corners have PVC or aluminum profiles sealed with silicone after assembly with oval surfaces that are flat and easy to clean.

Automation and Control

Touch-screen for ease of use. Monitoring of differential pressures, temperature, humidity and particle count values for each zone. Management of alarms, electrical outlets, UV lambs and light fittings. Display of airflow rates, particle count, filter occupancy, and air quality data. Stand-by mode with adjustable run timing.

Pass-Boxes

Available in static and dynamic types. Dynamic type with 500 m3/h or more airflow, passed through H14 Hepa filters. Interlock system to provide the best workflow and air quality. Stainless steel material in inner and outer surfaces. Acrylic window doors for a clear view of the internal chamber.

Windows

Flush type with the same thickness of door/wall. Bonded and sealed to an aluminum frame with tempered glass. Sealed with silicone caulk. Positioned per customer needs.

Doors

Interlock system to provide the best workflow and air quality. PVDF coated hygienic surfaces on both sides. Magnetic safety lock with password protection. Optional width between 90-120cm.

Optional

Accessories

- Stainless steel hand basin

- Portable stainless steel workbench

- Shoe racks and clean wardrobes with filters

- Automatic door closer and opener

- Cleanroom Stools

- Dynamic/Static type pass-through boxes with interlock system

Cleanroom

Classification